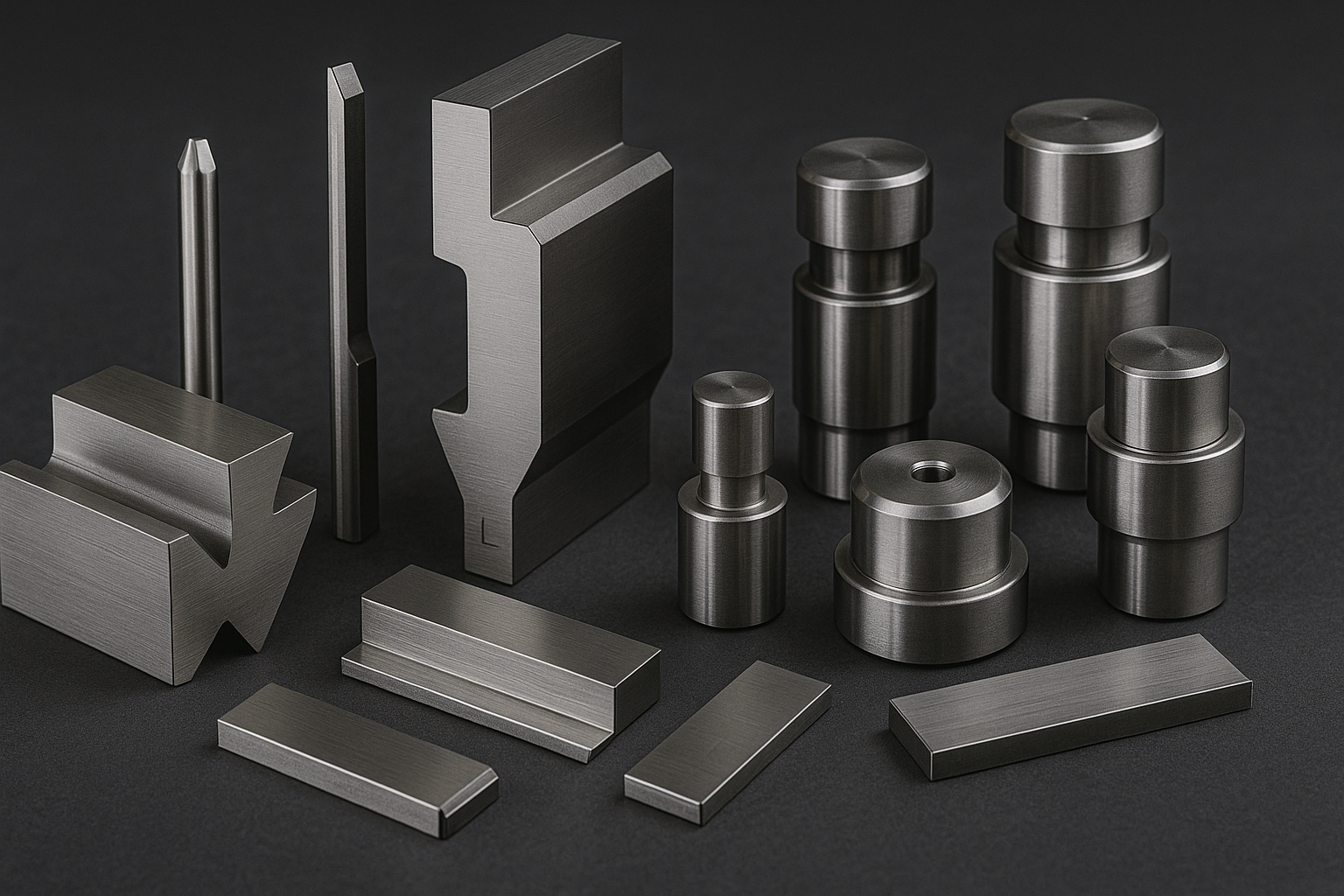

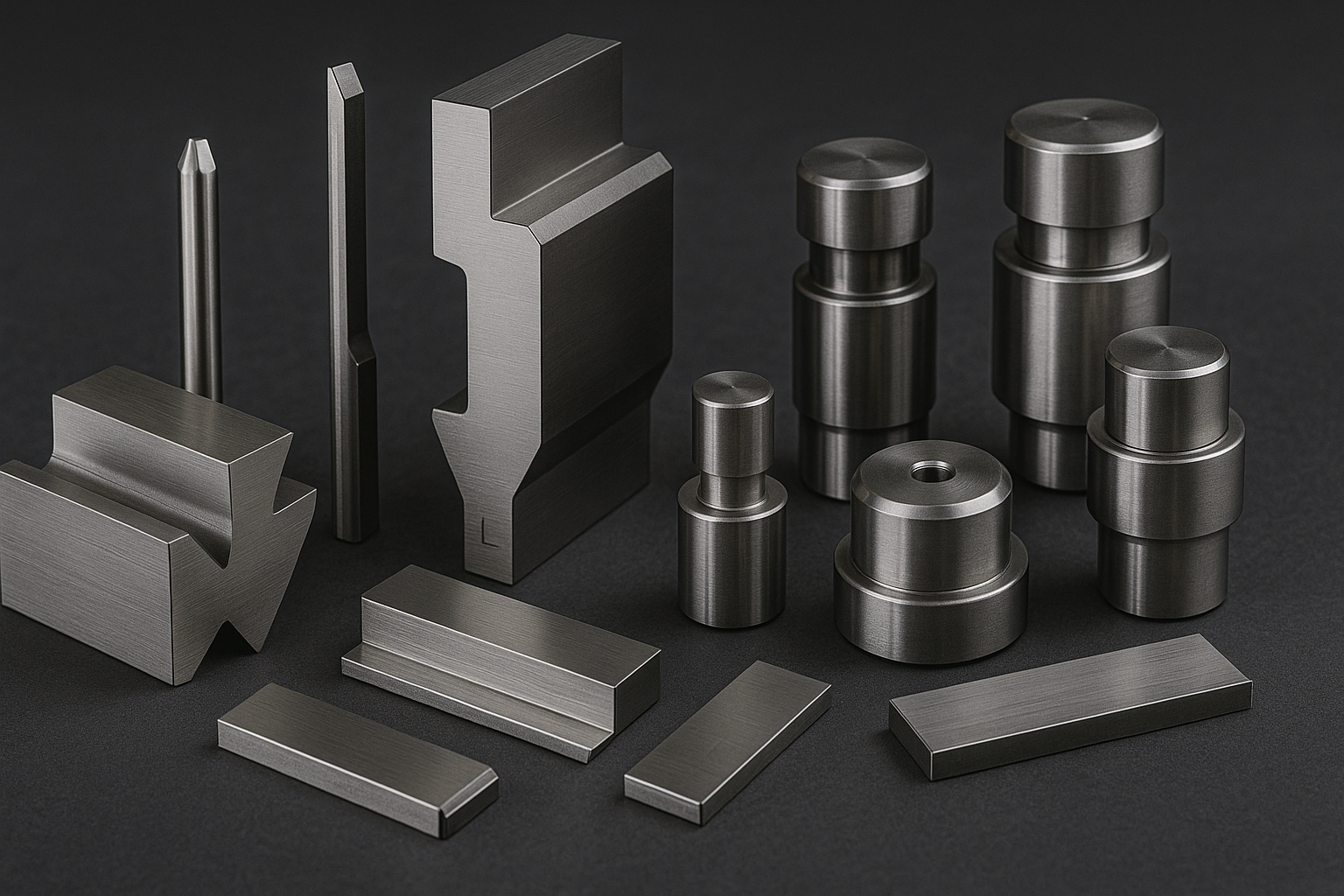

High-quality press brake tooling is essential for precision bending and long-term performance. Crafted from premium steel, induction hardened to 55–60 HRC, and finished with fine grinding, these punches, dies, and adapters are built for durability and accuracy. Now available through Machinist’s Vault, a full range of European-style press brake tooling is ready to ship across North America. Whether you need standard or custom solutions, you’ll get expert-backed support, fast fulfillment, and tooling you can trust for every bend.